Eco-challenge Project

What is the Eco-Challenge?

As part of our environmental protection activities, we will review the working environment, including temperature, operating hours, and quality, and look for optimal management.

Purpose

- Improvement of awareness of on-site improvement in manufacturing areas, etc.

- Development of on-site-led improvement activities

- Development of field improvement leaders

Target

(1) Reduction of energy consumption

(2) Finding opportunities for on-site improvement (improving work efficiency)

Current challenge

・Basic seminar on energy conservation

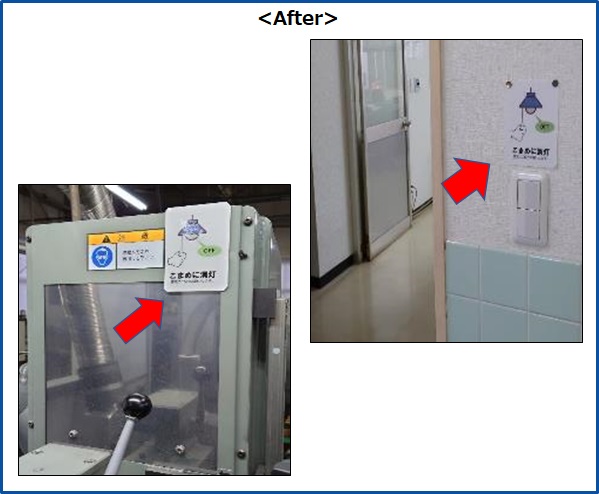

・Lighting cut-off and lighting off when not needed

・Cleaning machine openings, windows, heat insulation of exhaust ducts, etc.

・To shield windows from heat and light

・Cover the outdoor unit with a snuff

・Adjusting the temperature required when using air conditioners and the comfort temperature of workers

・Response to air leaks from compressors

|

|

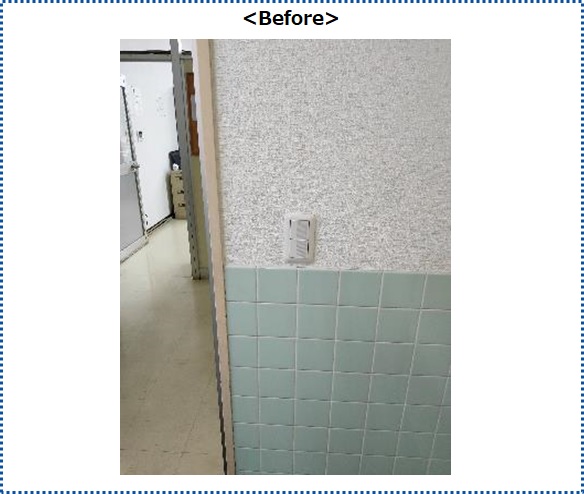

By posting a bulletin where an electric switch is present or where the machine is visible,

Electricity conservation awareness is gradually increasing, and there is less forgetting to turn off electricity.

|

|

The temperature at the window before applying the air packing is 42℃,

After application, the temperature was reduced by -4°C at 38°C.

Photovoltaic Power Generation

Since March 2013, we have installed photovoltaic power generation facilities to create environmentally friendly clean energy.

[Outline of photovoltaic power generation facilities]

Installed at the Kofu Factory of Seki Corporation

Annual power generation: Approx. 120,000 kWh/year

Reduction in CO2 emissions: Approx. 37,800 kg (Annual CO2 absorption of approximately 2,700 cedar trees)

※Annual CO2 absorption per cedar tree averages 14 kg

We will continue to actively promote the use of environment-friendly clean energy sources, such as the reduction of CO2 emissions.

To improve the working environment for our employees, we renovated our cafeterias and toilets.

・Cafeteria

Before |

After |

・Rest Room and Locker

|

|